electrical conduit installation guide pdf

Electrical conduit installation is a vital skill, ensuring safe and compliant wiring systems. This guide details planning, techniques, and regulations for effective conduit runs.

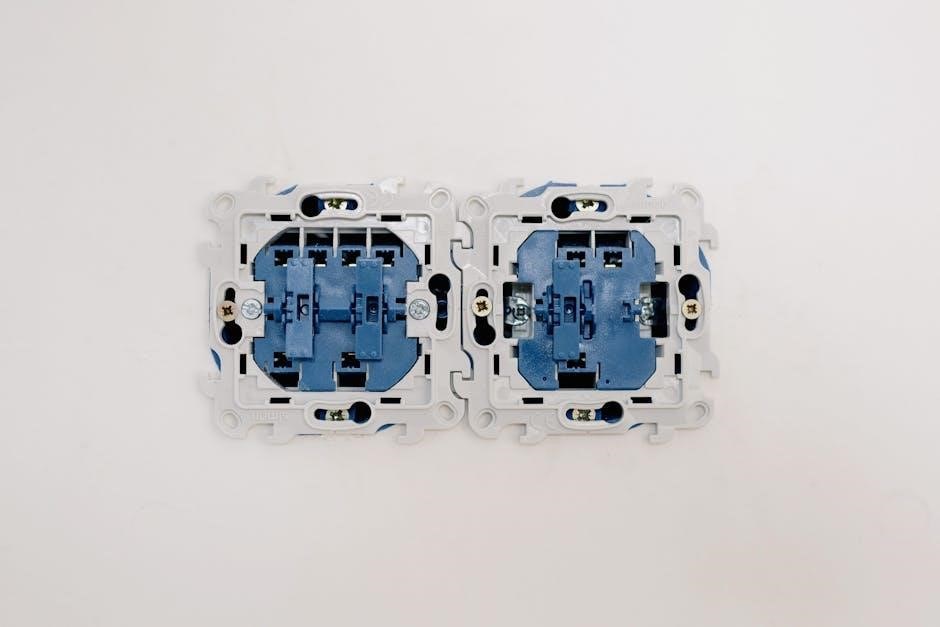

What is Electrical Conduit?

Electrical conduit is a tubular protective system for electrical wiring. It acts as a pathway for wires, shielding them from impact, moisture, and chemical damage. Commonly constructed from metal or plastic, conduit provides a grounded, safe enclosure for electrical conductors.

Different types, like Rigid Metal Conduit (RMC), EMT, and PVC, cater to varying installation needs and environments. Conduit systems aren’t just about protection; they also contribute to the overall safety and longevity of electrical installations. Proper selection and installation, adhering to standards like the NEC, are crucial for a reliable and code-compliant system. It’s a fundamental component of robust electrical infrastructure.

Why Use Electrical Conduit?

Employing electrical conduit offers substantial benefits beyond basic wire protection. It significantly enhances safety by safeguarding against physical damage, preventing shorts and electrical fires. Conduit systems provide a grounded path, minimizing electrical shock hazards. Furthermore, they offer superior protection in harsh environments, resisting moisture, chemicals, and corrosion.

Conduit also supports code compliance, satisfying stringent building regulations and inspection requirements. It allows for easier future upgrades or modifications to wiring without disturbing surrounding structures. Choosing conduit demonstrates a commitment to long-term reliability and a professional, robust electrical installation, increasing property value and peace of mind.

Types of Electrical Conduit

Various conduit types – RMC, IMC, EMT, FMC, LFMC, and PVC – cater to diverse installation needs, offering different levels of protection and flexibility.

Rigid Metal Conduit (RMC)

Rigid Metal Conduit (RMC) is a heavy-duty galvanized steel tubing providing exceptional protection for electrical wiring. It’s renowned for its robustness, making it ideal for exposed and underground installations where physical damage is a concern. RMC requires threading for connections, utilizing threaded fittings to create secure, watertight joints.

Due to its thickness, RMC offers superior mechanical strength and resistance to corrosion. However, this strength comes with increased weight and installation complexity. Cutting and bending RMC necessitate specialized tools, and proper grounding is crucial for safety. It’s often selected when maximum protection is paramount, adhering strictly to the National Electrical Code (NEC) guidelines for appropriate applications and installation practices.

Intermediate Metal Conduit (IMC)

Intermediate Metal Conduit (IMC) presents a balance between the strength of Rigid Metal Conduit (RMC) and the lighter weight of Electrical Metallic Tubing (EMT). Constructed from galvanized steel, IMC offers substantial mechanical protection for conductors, suitable for various indoor and outdoor applications. While requiring threading like RMC, IMC’s thinner walls simplify bending and cutting compared to its heavier counterpart.

IMC is a cost-effective alternative when RMC’s extreme durability isn’t essential, yet a robust solution is still needed. Proper installation, including secure support and grounding, is vital. Always consult the National Electrical Code (NEC) to ensure IMC is appropriate for the specific installation environment and load requirements, maximizing safety and longevity.

Electrical Metallic Tubing (EMT)

Electrical Metallic Tubing (EMT), often called thinwall conduit, is a lightweight, pre-galvanized steel tubing widely used for indoor wiring applications. Unlike Rigid Metal Conduit (RMC), EMT doesn’t require threading for joining sections, utilizing compression fittings instead, simplifying installation. This makes it a popular choice for exposed runs in commercial buildings and residential spaces.

However, EMT offers less mechanical protection than RMC and isn’t suitable for direct burial. The National Electrical Code (NEC) dictates specific requirements for extending circuits with EMT, considering electrical loads. While straightforward, proper installation—including correct support and secure connections—is crucial for a safe and compliant electrical system.

Flexible Metal Conduit (FMC)

Flexible Metal Conduit (FMC) provides a versatile solution for electrical wiring in dry locations where some flexibility is needed. Its interlocked construction allows for bending without kinking, making it ideal for connecting moving parts or navigating tight spaces. FMC is commonly used for short runs to motors, appliances, or lighting fixtures.

However, FMC must be supported within 18 inches of each fitting and every three feet thereafter. It’s crucial to avoid sharp bends that could damage the conduit’s integrity. While offering flexibility, FMC provides limited physical protection and isn’t suitable for exposed outdoor applications without additional protection.

Liquidtight Flexible Metal Conduit (LFMC)

Liquidtight Flexible Metal Conduit (LFMC) is designed for wet or damp locations, offering superior protection against moisture, oils, and other corrosive substances. Its construction includes a liquid-tight jacket over a flexible metal core, ensuring a sealed system. LFMC is frequently used in applications like machine tool wiring, food processing plants, and outdoor installations where exposure to the elements is unavoidable.

Proper installation requires using liquidtight fittings specifically designed for LFMC. Like FMC, LFMC needs adequate support, typically within 18 inches of fittings and every three feet. It’s essential to avoid damaging the jacket during installation to maintain its liquid-tight properties.

PVC Conduit

PVC (Polyvinyl Chloride) conduit is a non-metallic, lightweight option ideal for corrosive environments and underground applications. It’s resistant to moisture, chemicals, and rust, making it a durable choice. PVC conduit is commonly used for direct burial, concrete encasement, and in areas where electrical isolation is needed. However, it’s crucial to protect PVC from physical damage, as it’s less impact-resistant than metal conduits.

Installation involves solvent cementing joints to create a watertight seal. Proper priming and cementing techniques are vital for a secure connection. PVC conduit requires expansion joints to accommodate thermal expansion and contraction, especially in outdoor installations.

Planning the Installation

Careful planning involves assessing the route, reviewing local codes, and determining conduit fill capacity for a safe, efficient, and compliant electrical system.

Evaluating the Installation Area

Begin by thoroughly assessing the planned route for your electrical conduit installation. Prioritize accessibility throughout the entire length, aiming for the shortest and most direct paths connecting electrical outlets and devices. This strategic approach minimizes material waste, reduces installation time, and ultimately contributes to a cleaner, more professional final appearance.

Consider potential obstructions like walls, ceilings, existing pipes, and ductwork. Note any areas requiring special attention, such as locations prone to physical damage or exposure to the elements. A detailed evaluation helps anticipate challenges and informs the selection of appropriate conduit types and support methods. Accurate assessment is paramount for a successful and long-lasting installation.

Reviewing Local Regulations and the NEC

Prior to commencing any conduit installation, a comprehensive understanding of local building codes and the National Electrical Code (NEC) is absolutely crucial. These regulations dictate permissible conduit types, installation methods, grounding requirements, and fill capacities, all designed to ensure electrical safety and prevent hazards.

Familiarize yourself with amendments to the NEC adopted by your local jurisdiction, as these can vary significantly. Compliance isn’t merely advisable; it’s legally mandated. Thoroughly review relevant sections pertaining to conduit installations, paying close attention to specific requirements for your application. Proper adherence guarantees a safe, code-compliant, and legally sound electrical system.

Determining Conduit Fill Capacity

Accurately calculating conduit fill capacity is paramount for safe and compliant electrical installations. The NEC strictly limits the percentage of a conduit’s cross-sectional area that can be occupied by conductors. Overfilling can lead to overheating, insulation damage, and potential fire hazards.

Fill capacity depends on the conduit type and the number of conductors. Tables within the NEC provide specific fill percentages for various scenarios. Consider conductor size, insulation type, and the presence of equipment grounding conductors when performing these calculations. Always prioritize safety and adhere to NEC guidelines to prevent costly and dangerous errors.

Installation Techniques

Proper installation involves precise cutting, bending, and joining of conduit sections, alongside secure support systems, ensuring a durable and code-compliant pathway for wiring.

Cutting and Bending Conduit

Accurate cutting and bending are fundamental to successful conduit installation. Utilize appropriate conduit cutters – saws, pipe cutters, or abrasive wheels – ensuring clean, burr-free cuts. Bending requires specialized conduit benders, matched to the conduit type and size, to achieve precise angles without kinking or flattening.

Carefully measure and mark bending locations, referencing bending charts for accurate results. Remember that different conduit materials (RMC, IMC, EMT) necessitate different bending techniques and tools. Always prioritize safety, wearing appropriate personal protective equipment (PPE) during cutting and bending operations. Proper bending minimizes the need for unnecessary fittings, creating smoother, more efficient conduit runs.

Threading Conduit (RMC & IMC)

Rigid Metal Conduit (RMC) and Intermediate Metal Conduit (IMC) require threading for secure, watertight connections. Utilize a conduit threading machine with the correct die size for the conduit diameter. Apply cutting oil liberally during threading to reduce friction and extend die life.

Ensure the conduit is securely clamped within the machine and thread at a consistent speed, avoiding excessive force. Inspect threads for burrs or imperfections, removing them with a deburring tool. Properly threaded conduit allows for tight, mechanically strong joints when coupled with appropriate fittings. Remember, EMT does not require threading, simplifying its installation process.

Joining Conduit Sections

Joining conduit sections securely is crucial for a safe and lasting electrical system. For RMC and IMC, utilize threaded couplings, tightening them firmly with two wrenches – one to hold the conduit and the other to tighten the coupling. Ensure proper engagement of the threads for a watertight seal.

EMT conduit utilizes set-screw or compression fittings. Set-screw fittings require tightening the screws evenly to compress the conduit within the fitting. Compression fittings rely on a tightening ring to create a secure connection. Always verify the fitting is compatible with the conduit type and size, and inspect connections for tightness post-installation.

Supporting Conduit Runs

Properly supporting conduit runs is essential for safety and code compliance. The National Electrical Code (NEC) dictates specific support intervals based on conduit type and size. Generally, conduit should be supported every 10 feet for straight runs, and within 3 feet of every outlet box, fitting, or termination.

Use appropriate supports like straps, clamps, or hangers designed for the specific conduit material. Ensure supports are securely fastened to building structures. Avoid over-tightening, which can damage the conduit. For heavier conduit like RMC, more robust supports are necessary to prevent sagging or strain on connections, maintaining a professional and secure installation.

Wiring within Conduit

Wiring within conduit requires careful attention to wire selection, insulation, and fill capacity, adhering to NEC guidelines for safe and effective electrical circuits.

Wire Selection and Insulation

Selecting the correct wire for conduit installations is paramount for safety and performance. Wire insulation types must match the environmental conditions and voltage requirements of the circuit. Common types include THHN, THWN, and XHHW, each offering varying degrees of heat and moisture resistance.

Consider the ampacity of the wire, ensuring it’s sufficient for the intended load. The National Electrical Code (NEC) provides tables for determining appropriate wire sizes based on conductor material, insulation type, and ambient temperature. Proper insulation prevents shorts, ground faults, and potential fire hazards. Always verify compatibility between the wire’s temperature rating and the conduit’s limitations.

Furthermore, ensure the wire is listed and labeled for use within a conduit system, meeting relevant safety standards.

Conduit Fill Calculations

Accurate conduit fill calculations are crucial for adhering to the National Electrical Code (NEC) and preventing overheating. The NEC dictates maximum fill percentages based on the number of conductors within the conduit. Exceeding these limits restricts heat dissipation, potentially damaging insulation and creating a fire risk.

Calculations consider the cross-sectional area of the conduit and the overall area occupied by the conductors, including insulation. Different conductor types have varying diameters. Online calculators and NEC tables simplify this process, providing allowable fill capacities for various conduit sizes and conductor combinations.

Proper fill ensures adequate space for future wire additions or replacements, maintaining long-term system integrity and safety.

Color Coding of Wires

Standardized wire color coding is paramount for safety and easy identification within conduit systems. Typically, a two-wire circuit utilizes one black wire for the hot (live) conductor, one white wire for the neutral, and one ground wire – often bare or green – for safety grounding.

Beyond basic circuits, color conventions extend to multi-wire systems. Red, blue, and other colors denote additional hot conductors. Consistent adherence to these codes minimizes the risk of miswiring during installation or future maintenance, preventing electrical shocks and equipment damage.

Always consult the NEC and local regulations for specific color coding requirements in your jurisdiction.

Grounding and Bonding

Effective grounding and bonding are crucial for safety, minimizing electrical shock hazards and protecting equipment. Proper implementation also addresses EMI concerns.

Grounding Conduit Systems

Grounding metal conduit is paramount for safety, creating a low-impedance path for fault currents back to the source. This minimizes shock hazards and facilitates rapid clearing of overcurrents. Metallic conduit systems must be effectively grounded, utilizing appropriate grounding bushings and bonding jumpers at all connections.

The conduit itself becomes part of the equipment grounding conductor when properly installed. Bonding ensures electrical continuity, connecting all metallic parts of the electrical system. Annex B highlights the importance of grounding and EMI considerations. Careful attention to grounding practices, as outlined in the NEC, is essential for a safe and reliable installation, preventing dangerous voltage buildup on metallic surfaces.

EMI Considerations and Shielding

Electromagnetic Interference (EMI) can disrupt sensitive electronic equipment. Metal conduit, particularly RMC and IMC, acts as a shield, attenuating EMI and Radio Frequency Interference (RFI). Proper grounding of the conduit system is crucial for this shielding effect to function effectively, creating a Faraday cage.

For applications requiring enhanced EMI protection, continuous bonding and overlapping conduit sections are recommended. Annex B details grounding and EMI considerations. Liquidtight Flexible Metal Conduit (LFMC) also provides shielding, but its effectiveness depends on maintaining electrical continuity. Careful installation practices, adhering to NEC guidelines, minimize EMI impact and ensure reliable operation of connected devices.

Special Considerations

Unique installations, like underground or hazardous location work, demand specific techniques and materials for safety and code compliance, as detailed in this guide.

Underground Conduit Installation

Buried conduit requires careful planning and execution to protect against physical damage and environmental factors. Proper depth is crucial, adhering to local codes and the NEC, typically a minimum of 18-24 inches.

Select conduit suitable for direct burial, like PVC or coated RMC, ensuring it’s appropriately marked. Bedding material, such as sand, should surround the conduit for cushioning and support.

Warning tape placed above the conduit alerts future excavators. Consider using concrete encasement in areas prone to heavy traffic or rockiness.

Always inspect the conduit for damage before backfilling, and ensure proper grounding techniques are employed for metallic conduit systems. Thorough documentation of the installation is essential for future maintenance and inspections.

Conduit Installation in Hazardous Locations

Installing conduit in hazardous locations—areas with flammable gases, dusts, or fibers—demands strict adherence to specific regulations outlined in the NEC (National Electrical Code). These locations are classified by zones or divisions based on the degree of hazard.

Explosion-proof conduit, fittings, and boxes are essential, designed to contain any internal explosion without igniting the surrounding atmosphere. Sealing conduit runs is critical to prevent the ingress of hazardous substances.

Metallic conduit systems must be properly grounded and bonded to dissipate static electricity.

Qualified personnel with specialized training are required for these installations, ensuring compliance with safety standards and minimizing the risk of ignition. Detailed documentation and inspection are paramount for ongoing safety.

Resources and Standards

Essential resources include the NEC (National Electrical Code) and ANSI standards, providing comprehensive guidelines for safe and compliant electrical conduit installations.

Reference Standards (NEC, ANSI)

Adhering to established standards is paramount for any electrical conduit installation. The National Electrical Code (NEC), published by the NFPA, serves as the cornerstone for safe electrical practices in the United States. It details requirements for conduit types, fill capacities, support spacing, and grounding procedures.

ANSI (American National Standards Institute) also plays a crucial role, developing consensus standards for conduit dimensions and materials. These standards ensure interchangeability and compatibility between different manufacturers’ products. Regularly consulting the latest editions of both the NEC and relevant ANSI standards is vital.

Furthermore, local amendments to the NEC often exist, so understanding regional building codes is equally important. Utilizing approved standards guarantees a secure, reliable, and legally compliant electrical system, minimizing risks and ensuring long-term performance.

Appendix: Conduit Dimensions Guide

A comprehensive conduit dimensions guide is essential for accurate material selection and installation planning. This appendix provides key data, including trade sizes, outer diameters, and wall thicknesses for various conduit types – RMC, IMC, EMT, and PVC. Understanding these dimensions is crucial for calculating conduit fill capacity, ensuring proper wire pulling, and selecting appropriate fittings.

The guide details internal areas for each conduit size, aiding in compliance with NEC regulations regarding conductor fill. It also outlines the weight per foot for different conduit materials, assisting with load calculations and support design. Accurate dimensions prevent overcrowding and potential damage to conductors.

Referencing this guide throughout the installation process ensures a professional and code-compliant result, optimizing system performance and safety.